With the development of biotechnology and the gradual expansion of the probiotic market, the production of probiotic freeze-dried powder has become an emerging industry. In the production of probiotic freeze-dried powder, the freeze-drying process is a crucial step that affects product quality and production efficiency. Shanghai Tuofen Freeze Drying Machine, as a professional manufacturer engaged in the design, manufacturing, and sales of freeze-drying equipment, provides a probiotic freeze-drying powder production solution with freeze-drying process technology and complete equipment.

1、 Selection and cultivation of bacterial strains

In the production of probiotic freeze-dried powder, select probiotic strains with excellent characteristics. These bacterial strains should have good tolerance, be able to survive in the production environment, and maintain good activity. The cultivation process needs to be carried out under strictly controlled conditions to ensure the purity and stability of the bacterial strains.

2、 Raw material preparation and processing

The raw materials required for producing probiotic freeze-dried powder mainly include culture medium, stabilizers, protectants, etc. The culture medium is the medium for the growth of probiotics, and it needs to be selected and configured according to the growth needs of the strain. Stabilizers and protectants are used to maintain the activity and stability of probiotics during the production process. Raw material processing includes steps such as cleaning and disinfection to remove impurities and harmful microorganisms.

3、 Fermentation and cultivation

Inoculate probiotics into the culture medium under appropriate temperature and pH conditions for fermentation and cultivation. During this process, the growth rate and metabolites of the bacterial strain will affect the quality and activity of the final product. By controlling the fermentation conditions, the yield and activity of probiotics can be increased.

4、 Concentration and extraction

After fermentation, it is necessary to isolate, concentrate, and extract probiotic bacteria. This step can be achieved through methods such as centrifugation and filtration. The extracted probiotics can be further processed into freeze-dried powder or other forms of probiotic products.

5、 Freeze drying processing

1. Design of Freeze Drying Process Parameters

The design of freeze-drying process parameters plays a crucial role in the quality and production efficiency of probiotics freeze-dried powder production. Based on the characteristics of probiotic freeze-dried powder, Shanghai Tuofen freeze-drying machine is scientifically designed and the freeze-drying process parameters are reasonably adjusted to ensure product quality and production efficiency.

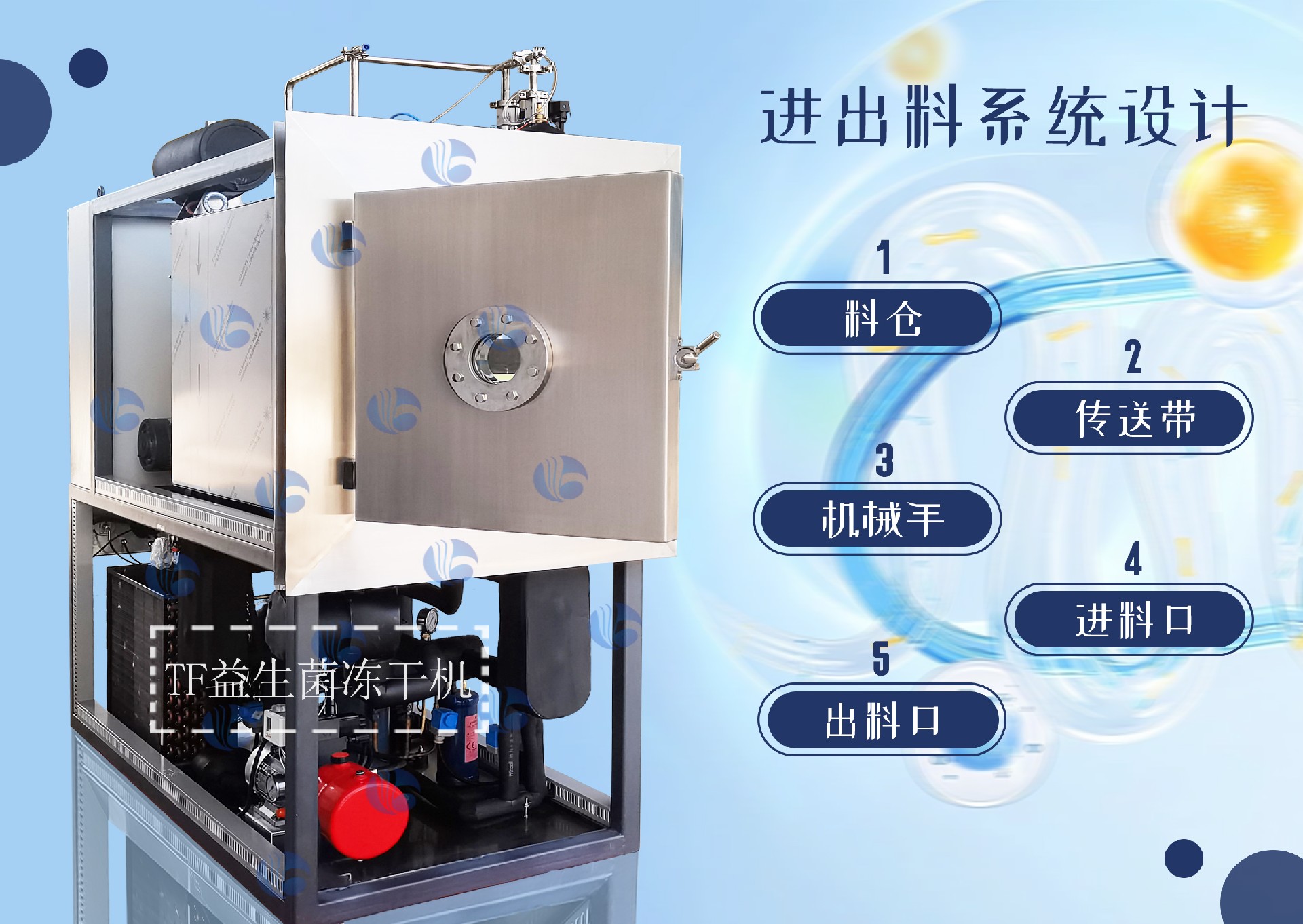

2. Design of material inlet and outlet system

Shanghai Tuofen freeze-drying machine adopts advanced automation technology and precise sensor control system to achieve automatic entry and exit of raw materials, avoid cross contamination and human operation errors, and improve production efficiency. The system includes a silo, conveyor belt, robotic arm, and feeding and discharging ports.

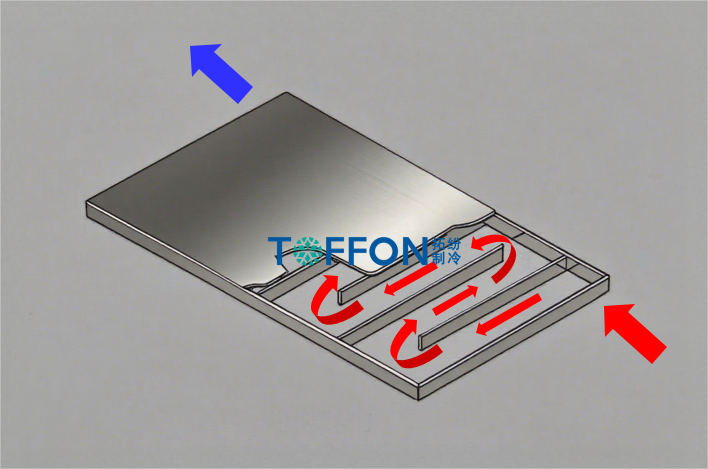

3. Temperature and humidity control

The Shanghai Tuofen freeze-drying machine adopts a precise temperature, vacuum and humidity control system to monitor and control the temperature, vacuum and humidity inside the freeze-drying box in real time, ensuring the quality and stability of probiotic freeze-dried powder. This system has the advantages of high efficiency, high sensitivity, and high stability, and can meet the strict requirements for temperature and humidity in the production of probiotic freeze-dried powder.

6、 Finished product quality inspection

The freeze-dried probiotic powder produced needs to undergo strict quality testing, including appearance, moisture content, strain purity, viable cell count, and other indicators.

7、 Packaging and Storage

Qualified products need to be packaged to protect probiotics from external environmental influences, maintain their activity and stability. Packaging materials should have good barrier properties to prevent the penetration of oxygen and moisture. During storage, the prescribed temperature and humidity conditions should be followed to ensure the quality and safety of probiotic freeze-dried powder.

Shanghai Tuofen freeze-drying machine provides a complete set of equipment and freeze-drying technology solutions for the production and processing of probiotic freeze-dried powder, which can ensure product quality and stability, improve production efficiency and reduce production costs. It is widely used in enterprises.

CN

CN English

English