The application of freeze-drying machines in water treatment, especially in sludge treatment, represents an important approach to resource utilization. Sludge treatment is a critical step in the water treatment process, and traditional treatment methods often suffer from problems such as large footprint, long treatment cycle, and high energy consumption. The introduction of freeze-drying technology provides an innovative and effective solution for sludge resource utilization.

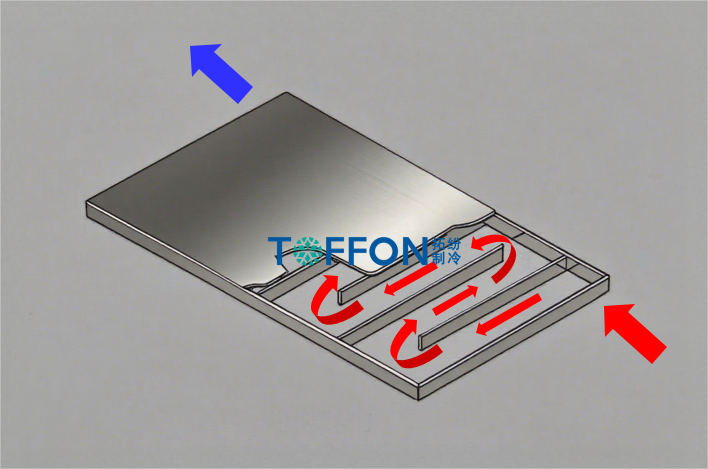

Freeze dryer utilizes the principles of freezing and vacuum sublimation to remove moisture from sludge, thereby dehydrating and drying the sludge. This process is divided into two main steps: first, the sludge is rapidly frozen at low temperatures to convert its moisture into solid ice crystals; Secondly, through sublimation in a vacuum environment, ice crystals are directly transformed into water vapor, thereby removing water from the sludge. This method can not only significantly reduce the volume and weight of sludge, but also effectively inhibit the activity of organic matter and pathogens in sludge, achieving higher treatment standards.

The advantages of freeze-drying technology in sludge treatment are mainly reflected in several aspects. Firstly, it significantly reduces the volume and weight of sludge, which is of great significance for subsequent transportation and disposal processes. The reduced volume not only lowers transportation costs, but also reduces the demand for processing facilities, thereby saving resources and energy. Secondly, during the freeze-drying process, due to low-temperature treatment, beneficial components in the sludge can be well preserved, such as certain reusable organic substances. This can further process these ingredients into fertilizers or other useful products, achieving the reuse of resources.

In addition, freeze-drying technology produces sludge with lower moisture content during the treatment process, making it easier to store and handle. Compared to traditional sludge treatment methods, the storage conditions for freeze-dried sludge are more flexible, which helps to reduce the complexity of storage and management.

However, the application of freeze-drying technology in sludge treatment also faces some challenges. For example, the high investment and operating costs of freeze-drying equipment may limit its popularity in some small-scale sewage treatment plants. At the same time, for large-scale sludge treatment, the processing capacity and efficiency of freeze-drying machines also need to be continuously improved to meet the demand for large-scale sludge treatment.

Overall, the application of freeze-drying machines in water treatment provides a resource-based solution for sludge treatment. By effectively reducing the volume of sludge, maintaining beneficial components, and simplifying the storage and treatment process, freeze-drying technology not only optimizes the sludge treatment process, but also promotes the process of sludge resource utilization. With the continuous advancement of technology and the gradual reduction of costs, freeze-drying machines are expected to play an increasingly important role in the field of sludge treatment.

CN

CN English

English