With the development of technology, traditional food processing methods are also constantly innovating. The emergence of bovine colostrum freeze-drying machines has brought revolutionary changes to the field of nutritional food. Colostrum, as a precious source of nutrition, is rich in immunoglobulin, vitamins, and minerals, which have significant effects on enhancing immunity and promoting health. However, the high nutritional content of colostrum also poses challenges in its preservation and transportation. In order to solve this problem, the bovine colostrum freeze-drying machine has emerged, providing an efficient and convenient technological solution.

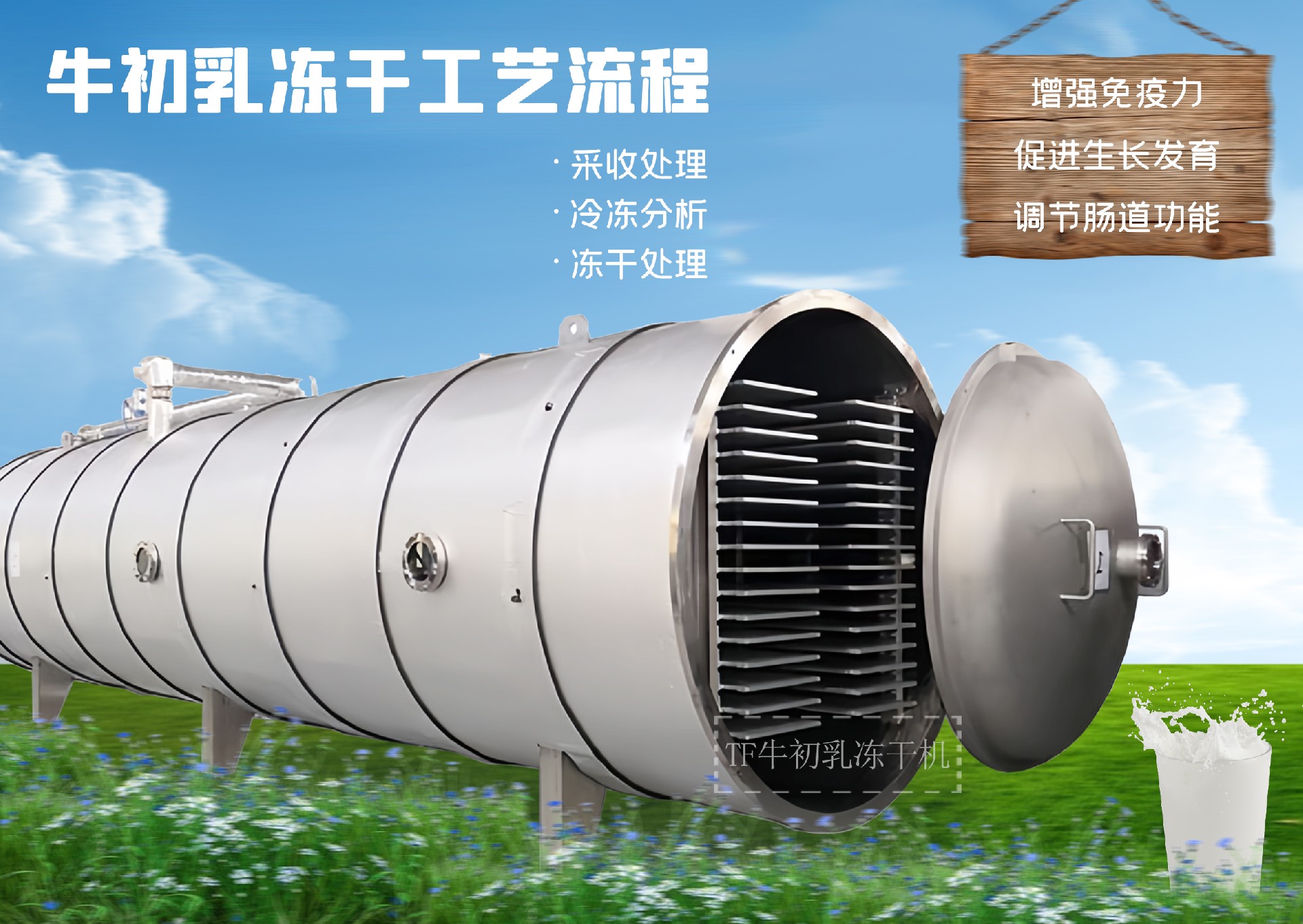

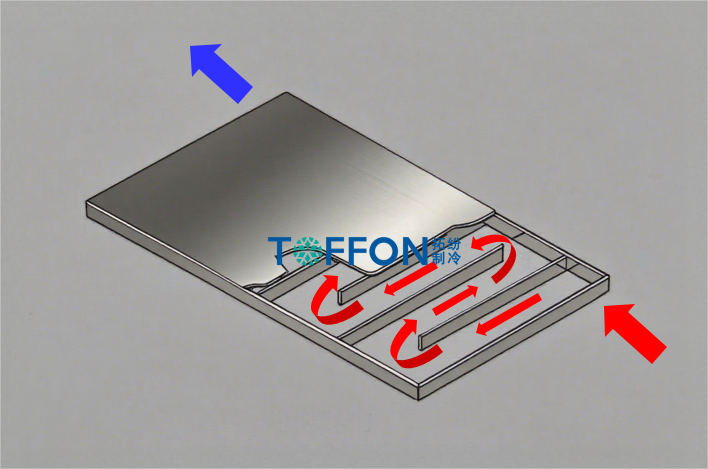

Freeze drying technology is an advanced food processing method, whose basic principle is to freeze liquid food first, and then directly sublime the ice into gas under vacuum to remove moisture. This method can maximize the preservation of the nutritional content and flavor of food, while avoiding the damage to the texture of food caused by traditional drying methods. Through this process, the colostrum lyophilizer removes the moisture in colostrum and retains the nutrient essence, making it more stable during storage and transportation.

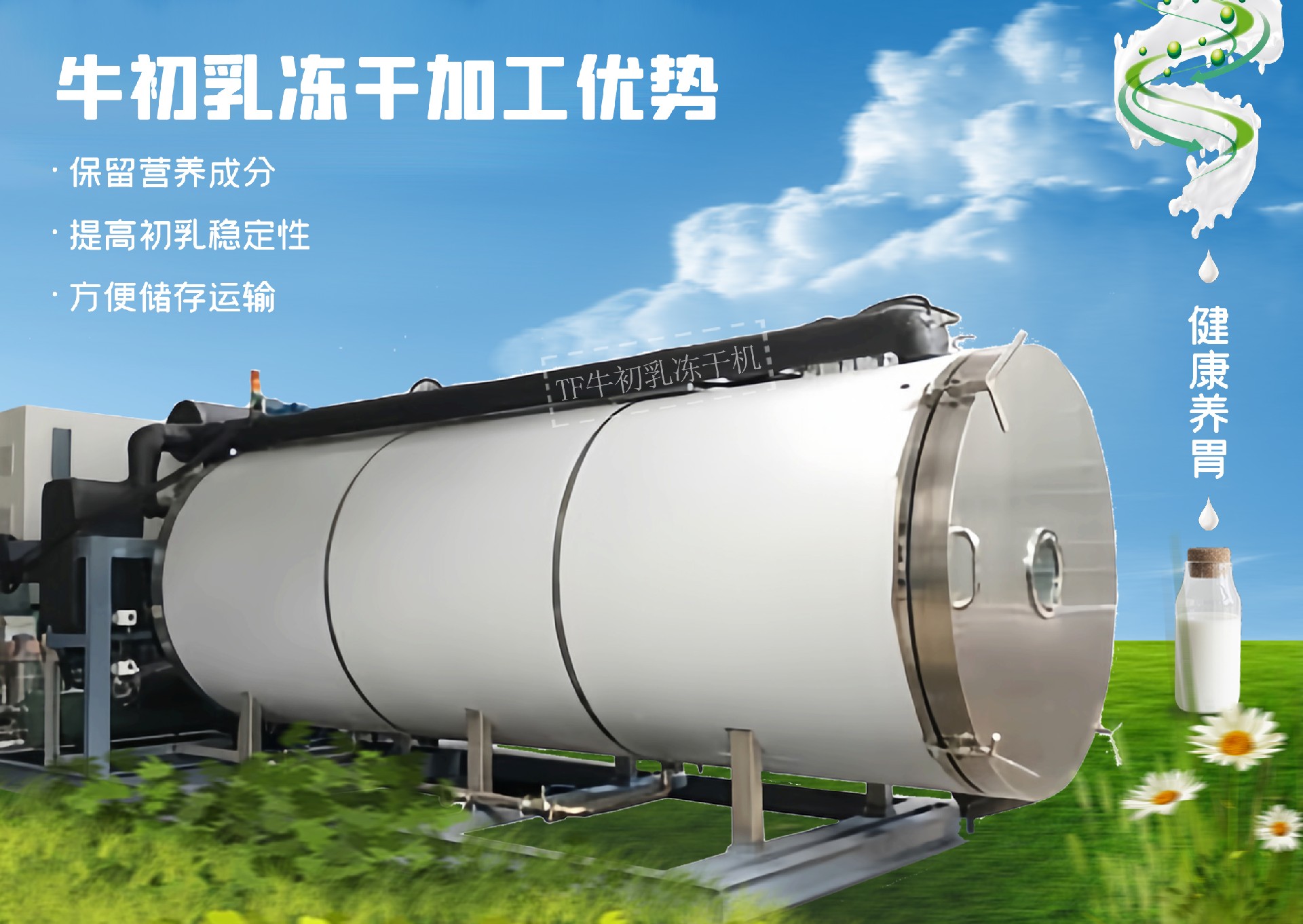

The application of bovine colostrum freeze-drying machine has multiple advantages. Firstly, it can effectively extend the shelf life of bovine colostrum. Traditional liquid colostrum is prone to spoilage at room temperature, while freeze-dried colostrum can be stored for a long time at room temperature, which facilitates logistics and sales. Secondly, freeze-drying technology can preserve the active ingredients in bovine colostrum, such as immunoglobulins and growth factors, allowing consumers to obtain the same nutritional value as fresh bovine colostrum when consuming freeze-dried colostrum.

In addition, the efficiency of the bovine colostrum freeze-drying machine is also reflected in its ease of operation. Modern freeze dryers are typically equipped with automatic control systems that can accurately adjust temperature and vacuum levels to ensure consistent drying results for each batch of colostrum. This efficient processing method not only improves production efficiency, but also reduces the cost of manual operations.

Overall, as a technological food processing solution, the bovine colostrum freeze-drying machine is leading the development trend in the field of nutritional food. It not only solves the limitations of traditional preservation methods, but also enhances the market competitiveness of colostrum. With the continuous advancement of technology, the future colostrum freeze-drying machine will demonstrate its unique value in more fields, bringing consumers richer nutritional choices.

CN

CN English

English