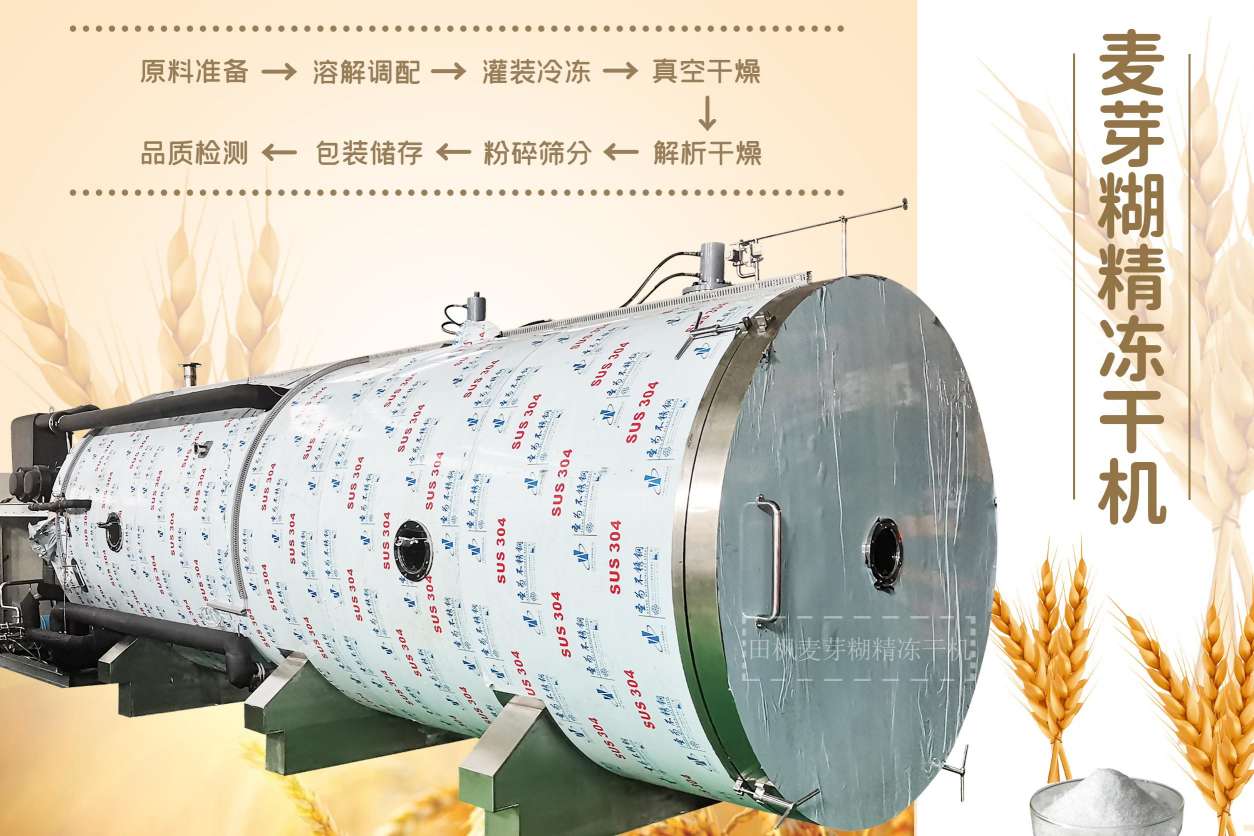

In the operation of freeze-drying machines, maltodextrin is a commonly used auxiliary material, and its pure quality is crucial for the quality of the final product. Maltodextrin is usually made from partially hydrolyzed starch and is widely used in fields such as food, medicine, and cosmetics. The establishment of freeze-drying machine standards must ensure the pure quality of maltodextrin to ensure the effectiveness and safety of the product.

Firstly, the purity of maltodextrin directly affects its stability during the freeze-drying process. High quality maltodextrin can be better mixed with other ingredients, improving the uniformity and taste of freeze-dried products. For example, in the food industry, the use of pure maltodextrin can effectively reduce odors and discoloration, and improve the overall quality of food.

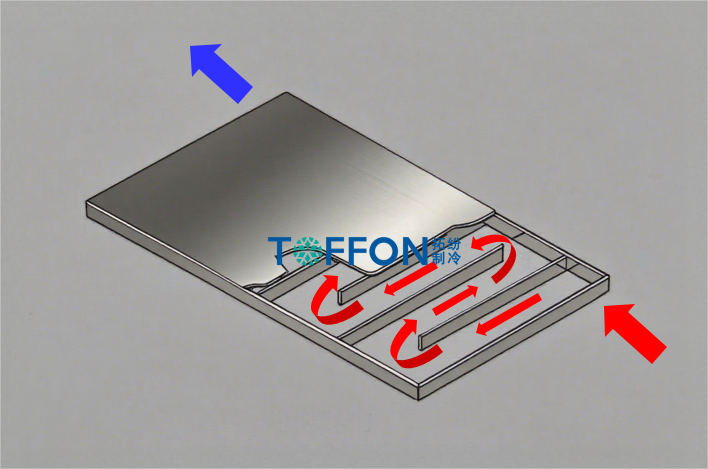

Secondly, the pure quality of maltodextrin is also related to the preservation and storage of freeze-dried products. During the freeze-drying process, the purity of maltodextrin determines its stability at low temperatures. Pure maltodextrin can better maintain its functionality during freeze-drying, avoiding clumping or spoilage, thereby extending the shelf life of the product.

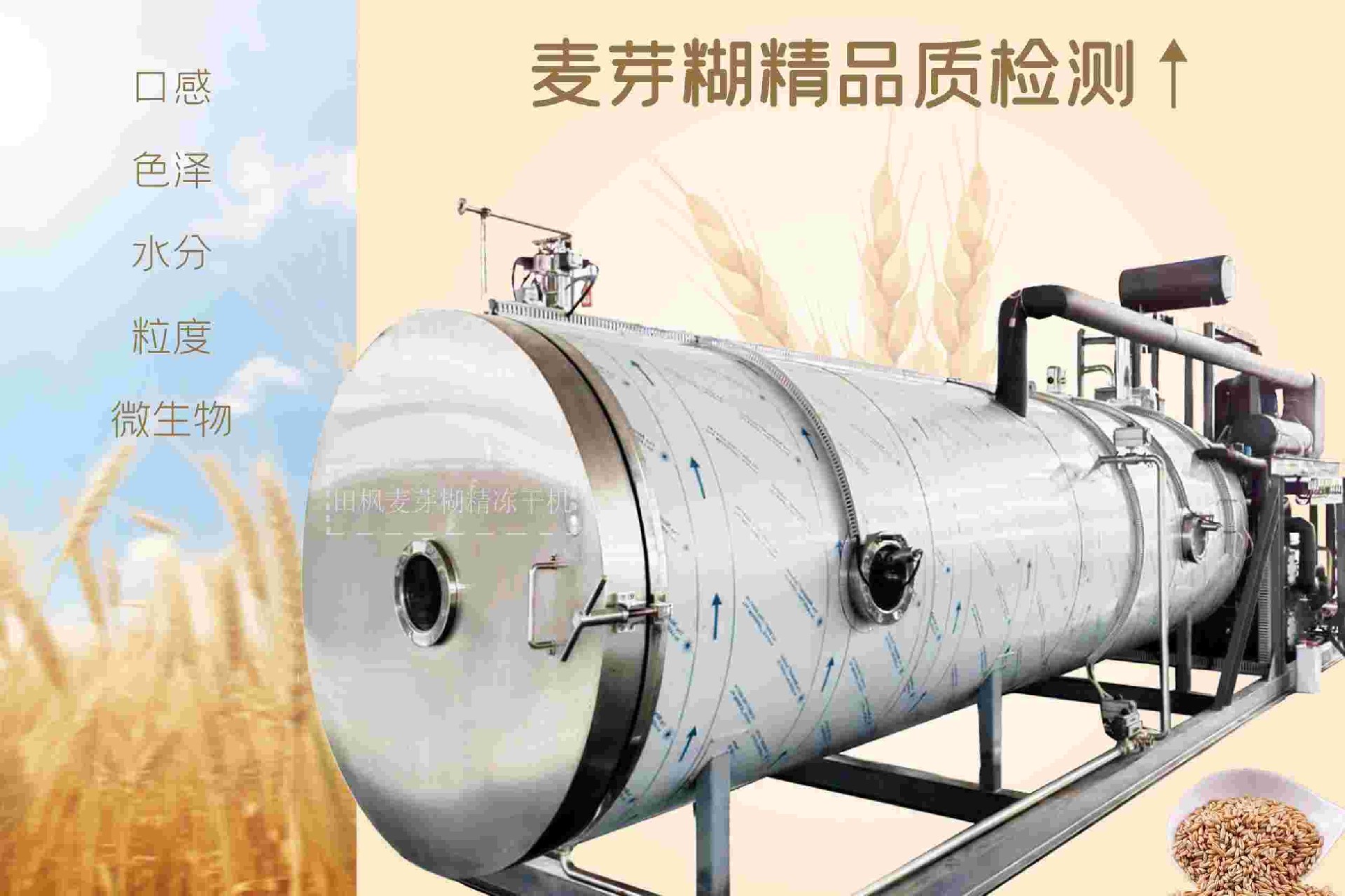

In practical operation, the standards for freeze-drying machines should include strict testing of the purity of maltodextrin. The quality of maltodextrin can be ensured to meet the standards through analytical methods such as high-performance liquid chromatography (HPLC). In addition, manufacturers need to strictly control the source of raw materials, select reliable suppliers, and conduct regular testing of maltodextrin to ensure that it meets food grade or pharmaceutical grade standards.

Ultimately, ensuring the purity and quality of maltodextrin is one of the key factors in ensuring the quality of freeze-dried products. Through strict standards and testing procedures, the quality and safety of freeze-dried products can be effectively improved. For consumers, choosing freeze-dried products with high-purity maltodextrin not only provides a better user experience, but also gives them more confidence in the reliability and stability of the product. Therefore, establishing and adhering to the purity quality assurance of maltodextrin in freeze-drying machine standards is an important guarantee for various industries to improve product quality and safety.

CN

CN English

English