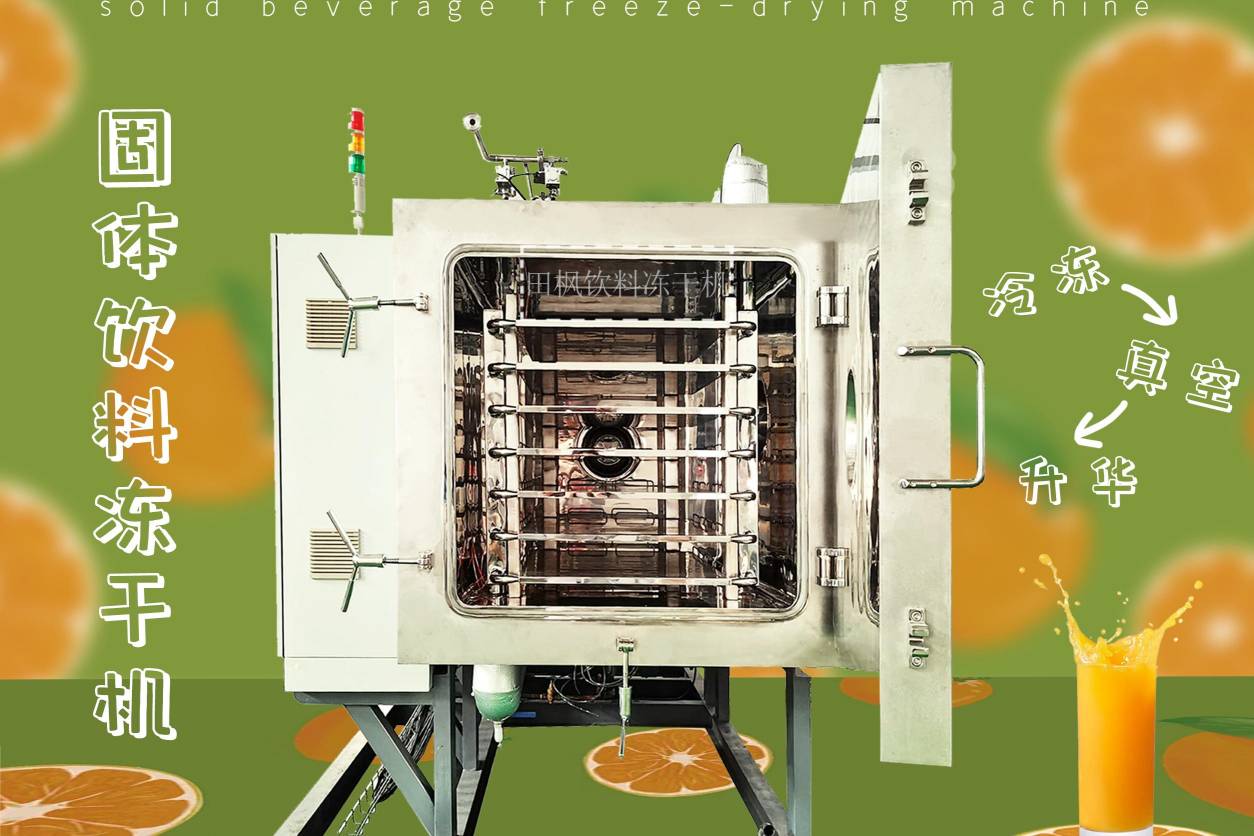

In today's food processing industry, freeze-drying technology has become an important means to ensure the purity and quality of solid beverages. The freeze-drying machine standard not only concerns the technical parameters of the equipment, but also directly affects the quality of the final product. By delving into the standards of freeze-drying machines, we can better grasp how to maintain the original flavor and nutritional content of solid beverages.

The freeze-drying process, also known as freeze-drying, involves freezing beverages to extremely low temperatures and directly converting the ice into gas to remove moisture. This process can maximize the retention of nutrients and flavor molecules in the beverage. The standards for freeze-drying machines involve multiple aspects such as temperature control accuracy, pressure control, and freezing speed of the equipment. These standards ensure the uniformity and stability of the freeze-drying process, enabling each batch of products to meet consistent quality requirements.

Firstly, the temperature control accuracy of the freeze dryer is one of the key factors determining the quality of solid beverages. Accurate temperature control can effectively prevent excessive freezing or insufficient drying of beverages during the freeze-drying process, which may lead to loss of nutrients or changes in flavor. High standard freeze dryers are usually equipped with advanced temperature control systems to ensure that the temperature at each stage is within the optimal range.

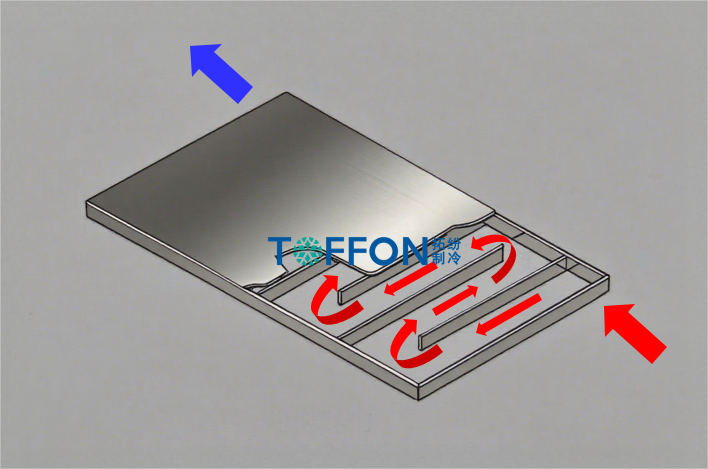

Secondly, pressure control of the freeze dryer is also crucial. The low-pressure environment during the freeze-drying process facilitates the sublimation of ice, therefore, the freeze-drying machine must have stable and accurate pressure regulation function. Good pressure control can not only improve drying efficiency, but also ensure the quality of the final product. A high-quality freeze dryer can maintain appropriate pressure throughout the entire process, thereby avoiding the occurrence of bubbles or clumping in solid beverages.

In addition, the freezing speed of the freeze dryer also has a direct impact on the quality of solid beverages. Rapid freezing can prevent the formation of large ice crystals when water freezes in beverages, which may damage the structure of the beverage and affect the final taste. A high standard freeze dryer can achieve fast and uniform freezing, thereby maintaining the original texture and flavor of the beverage.

In short, the standards of freeze-drying machines directly determine the purity and quality of solid beverages. By understanding and applying these standards, manufacturers can effectively improve product quality and ensure that every bottle of solid beverage provides consumers with the best experience.

CN

CN English

English