Milk contains various nutrients such as protein, fat, carbohydrates, vitamins, and minerals, which play an important role in human health. In traditional production and processing, milk is usually disinfected, processed, and packaged before being sold. Milk freeze-dried powder is a powdered product obtained by processing milk through freeze-drying technology. It is made from fresh milk through freezing, freeze-drying, and crushing steps using milk freeze-drying technology. After being processed by a complete set of equipment in the milk freeze-dried powder production line, the original nutritional components of milk can be preserved, and it is easy to store, transport, and use, which has been widely used in many fields.

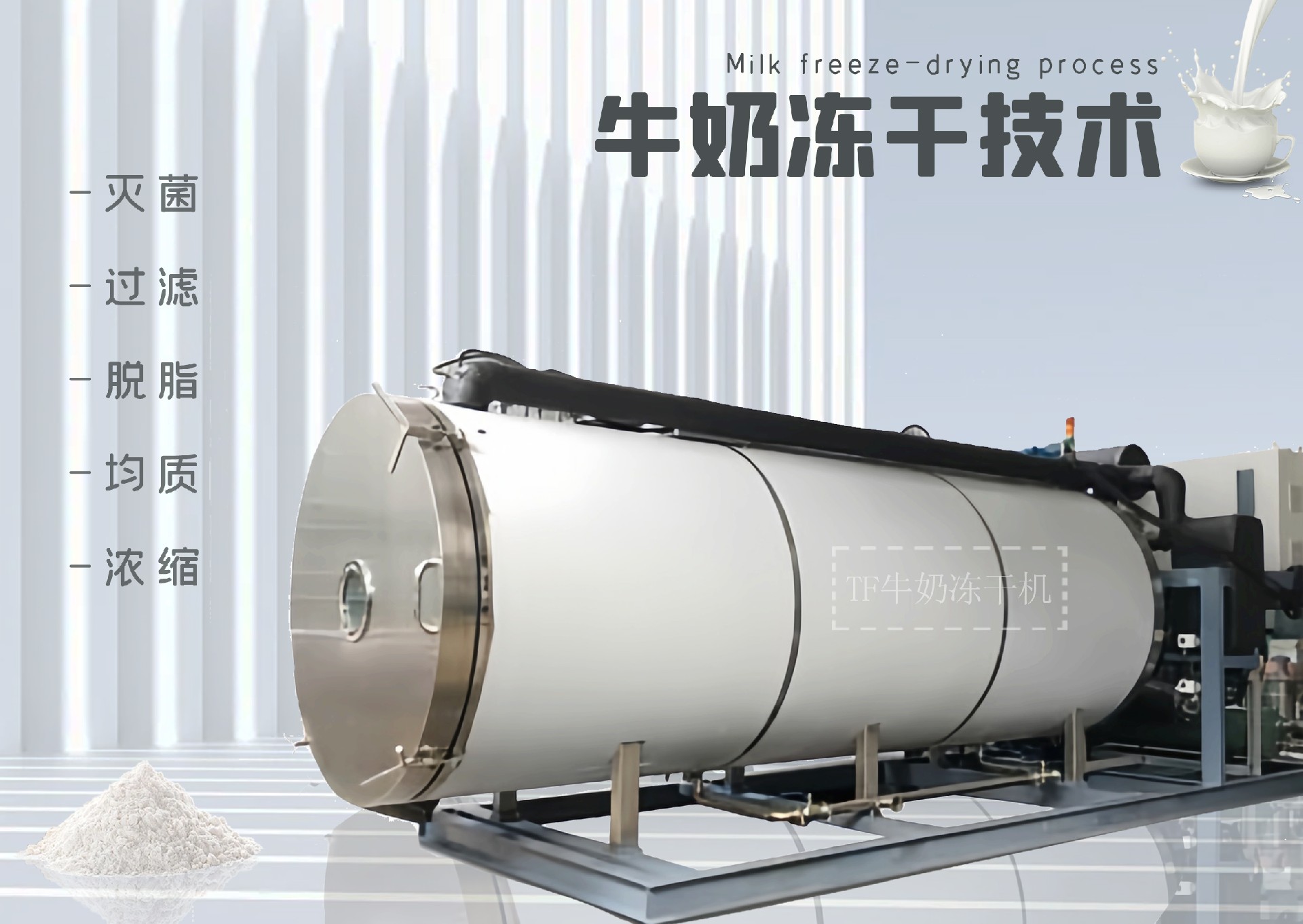

1、 Milk freeze-drying technology

1. Introduction to Milk Freeze Drying Process

The freeze-drying process of milk mainly includes the following steps: firstly, milk pretreatment, which involves standardizing, sterilizing, filtering, defatting, homogenizing, and concentrating the raw milk to ensure its purity and stability; Next is freezing treatment, which involves freezing the processed milk into a solid through a quick freezing warehouse, followed by vacuum drying treatment. The frozen milk solid is then subjected to vacuum environment, where the solid ice is directly sublimated into gas to remove it, and then crushed at low temperature to obtain freeze-dried milk powder.

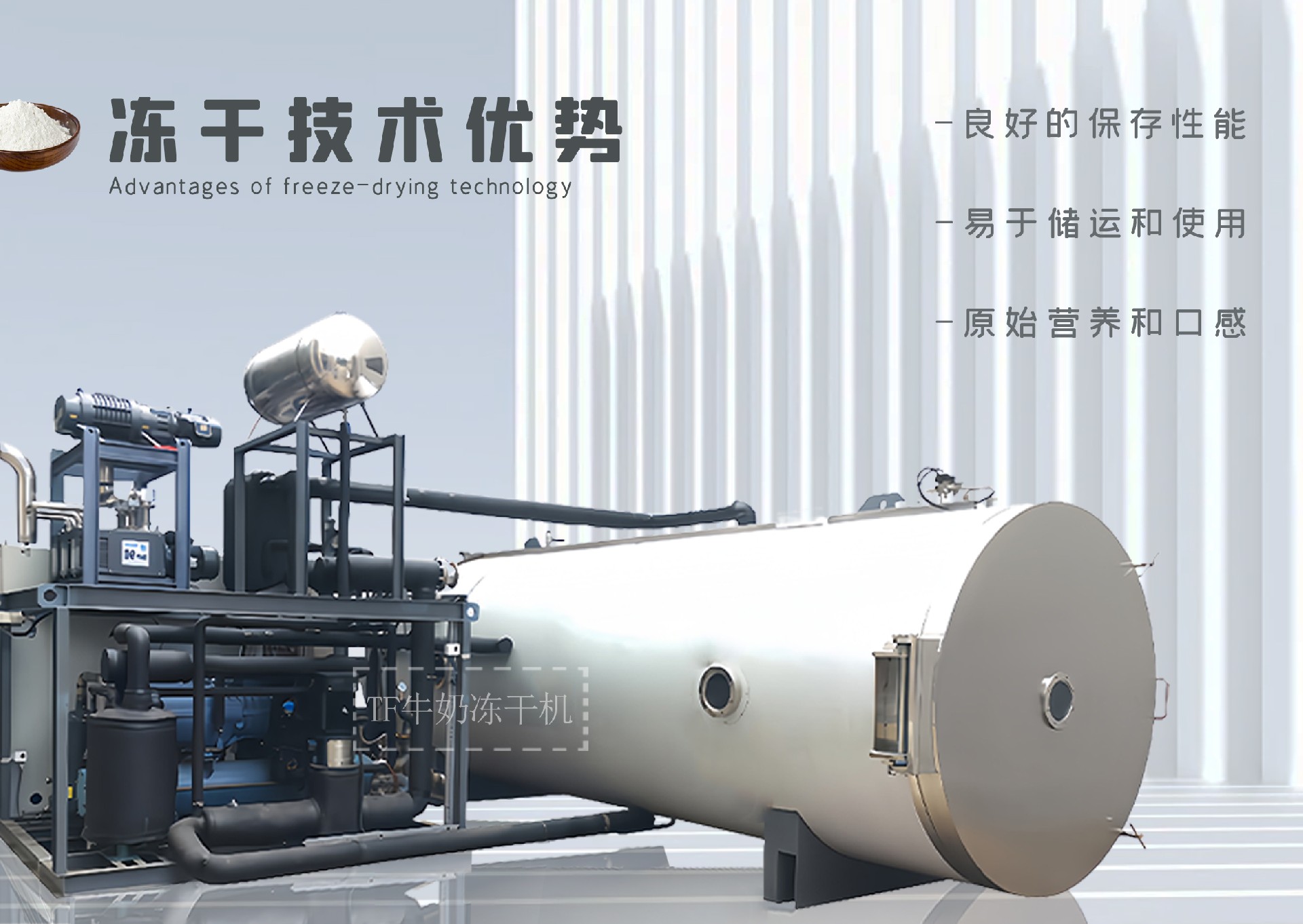

2. Advantages of Milk Freeze Drying Technology

The freeze-drying technology of milk has the following advantages:

(1) Good storage performance: The moisture content of milk freeze-dried powder is removed by 95-99%, allowing it to be stored for a long time at room temperature without spoilage.

(2) Easy to store and use: Milk freeze-dried powder can be packaged and sealed for convenient storage, transportation, and use, and only requires the addition of an appropriate amount of water during use.

(3) Maintaining the original nutritional value and taste of milk: In the freeze-drying process of milk, the original nutrients, color, and taste of milk are preserved.

2、 Complete set of equipment for milk freeze-drying powder production line

The complete set of equipment for milk freeze-drying powder production line is the key equipment for realizing the milk freeze-drying process, which mainly includes the following parts:

1) Milk pre-treatment equipment includes milk purifiers, filters, pasteurizers, defatting machines, homogenizers, etc., used for pre-treatment and purification of raw milk.

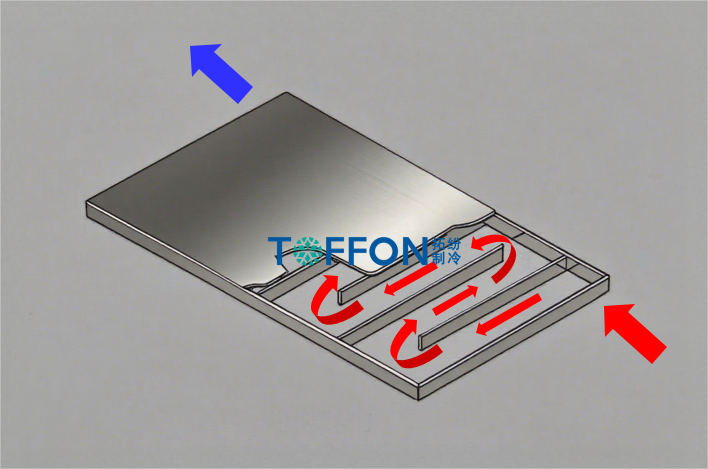

2) Freeze drying equipment mainly includes quick freezing machines and vacuum freeze-drying machines, which are used to freeze milk and perform low-temperature vacuum freeze-drying treatment.

3) The crushing equipment is used to low-temperature crush freeze-dried milk chunks into powder form.

4) Mixing equipment is used to mix freeze-dried milk powder with substances such as glucose and vitamins. Common equipment includes mixers or mixers.

5) Packaging equipment is used to package mixed milk freeze-dried powder. Common equipment includes automatic packaging machines or manual packaging machines.

6) Testing equipment is used to test the quality of milk freeze-dried powder, such as powder moisture content, particle size, etc. Common equipment includes moisture meters, particle size analyzers, etc.

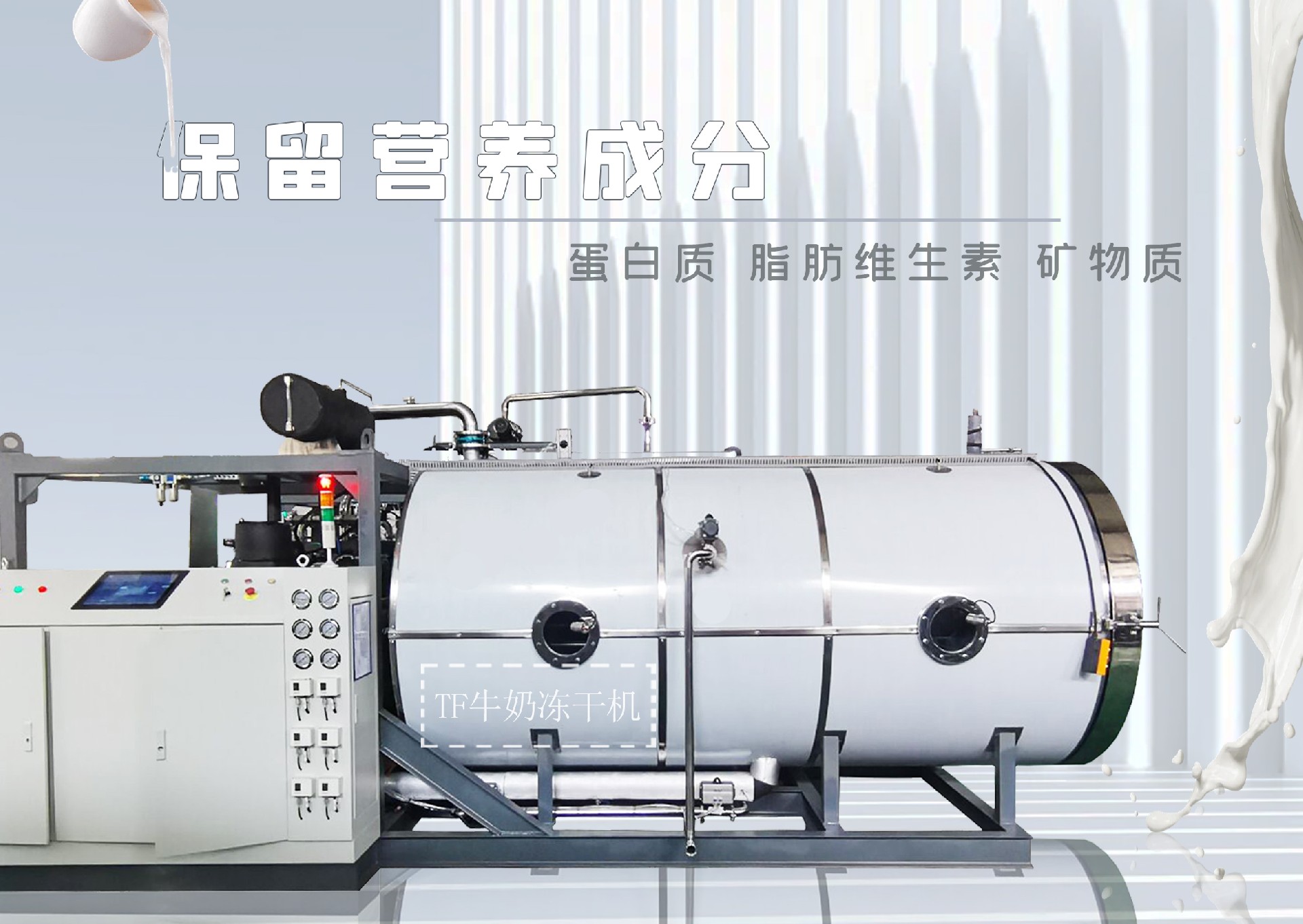

Milk freeze-dried powder retains the nutritional components of milk during the production process, including protein, fat, vitamins, and minerals. Therefore, it can provide nutritional value similar to fresh milk. The complete set of equipment for milk freeze-dried powder production line varies depending on factors such as production scale, process flow, and product requirements. Provide milk freeze-drying technology, milk freeze-drying production solutions, and turnkey engineering services for milk deep processing enterprises.

CN

CN English

English