With the increasing emphasis on healthy eating, vegetables have become popular as a healthy and nutritious food. However, due to the perishable nature of fresh vegetables and high storage and transportation costs, traditional vegetable processing methods are no longer able to meet market demand. In the context of current socio-economic and technological development, fully automatic vegetable freeze-drying machine production lines can not only improve the efficiency and quality of agricultural product processing, but also effectively reduce production costs and promote the rapid development of agricultural modernization.

The fully automatic vegetable freeze-drying machine production line is an automated production equipment mainly used to retain the nutritional components in vegetables, extend the shelf life of vegetables, and facilitate storage and carrying. This production line includes multiple processes such as cleaning, slicing, pretreatment, vacuum freezing, vacuum drying, etc., which can achieve automated processing of vegetables from raw materials to finished products.

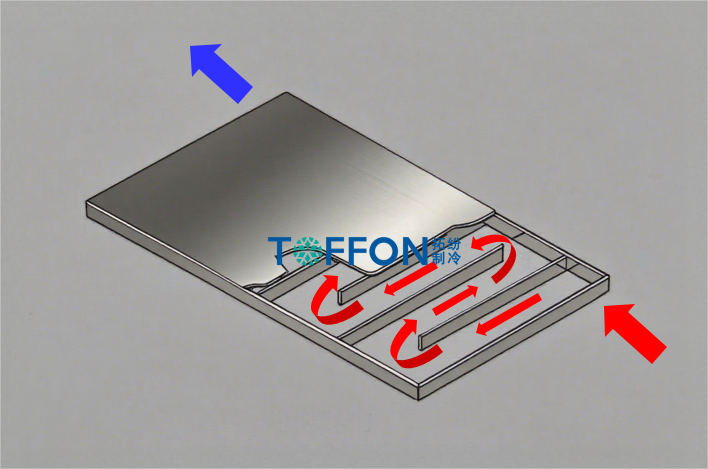

In the cleaning process of the production line, advanced cleaning techniques can effectively remove dirt and pesticide residues on the surface of vegetables. Secondly, in the slicing and preprocessing process, the fully automatic vegetable freeze-drying machine production line can perform different slicing and processing methods according to the type and requirements of vegetables, in order to better preserve the nutritional content of vegetables. Next, in the vacuum freezing process, low-temperature freezing of vegetables can effectively prevent the surface moisture of vegetables from freezing, thereby avoiding a decrease in vegetable quality. Then, in the vacuum drying process, vegetables are dried in a vacuum environment to remove moisture through sublimation, achieving the effect of freeze-drying, which can retain the nutrients in vegetables and extend their shelf life.

The fully automatic vegetable freeze-drying machine production line has the following characteristics:

High degree of automation: The fully automatic vegetable freeze-drying machine production line adopts CNC automation technology, realizing the fully automated processing process from raw materials to finished products, improving production efficiency and reducing labor input.

High product quality: The fully automatic vegetable freeze-drying machine production line can precisely control each process during the processing, ensuring that the nutritional components of vegetables are preserved, while also ensuring the shape, taste, and color of the products.

Low production cost: The fully automatic vegetable freeze-drying machine production line adopts an efficient production method, reducing manpower and material resources input, thereby reducing production costs and improving the competitiveness of the enterprise.

Strong adaptability: The fully automatic vegetable freeze-drying machine production line can process different types and requirements of vegetables, with strong adaptability to meet market demand.

The fully automatic vegetable freeze-drying machine production line can process different types and requirements of vegetables, with high automation, precise control, strong stability, and strong adaptability, improving efficiency and reducing costs. The fully automatic vegetable freeze-drying machine production line has achieved a fully automated processing process from raw materials to finished products, greatly improving production efficiency, effectively reducing labor input, and also reducing errors and losses in the production process. This enables the production line to meet the deep processing needs of vegetables in different regions and markets, and also provides a good guarantee for the development of agricultural modernization.

CN

CN English

English