TOFFON Freeze Dryer - Electrical Control System of Freeze Dryers (Part Seven)

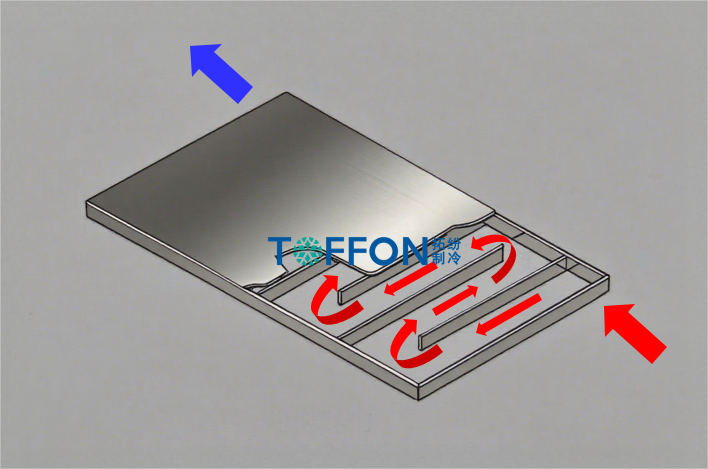

The PLC-based electrical control system of the freeze dryer is responsible for coordinating and controlling the operation of multiple subsystems, including refrigeration, heating, vacuum, and circulation. By integrating various sensors such as temperature, pressure, humidity, and liquid level sensors, the system collects real-time operational data from the freeze-drying chamber and other key components. The data is clearly displayed on a touchscreen interface in graphical form, allowing operators to intuitively monitor real-time operating status, process curves, alarm information, and historical records.

The electrical control system supports multiple control modes: manual operation, semi-automatic operation, and fully automated program control. Users can flexibly set freeze-drying process parameters based on actual needs, including cooling rate and holding time during the pre-freezing stage, vacuum level and shelf temperature control during the sublimation drying stage, and temperature ramp rate during the desorption drying stage.

The system enables comprehensive data recording and export throughout the entire freeze-drying process, meeting the stringent traceability requirements of new GMP regulations. In terms of safety protection, the control system is equipped with robust interlock and alarm mechanisms. For example, in cases of abnormal high pressure in the refrigeration system, vacuum pump overload, heating overtemperature, or door seal failure, the system will automatically trigger alarms and execute predefined protective actions such as shutdown or cooling to maximize the safety of both the equipment and the products.

Additionally, the freeze dryer supports remote monitoring, enabling real-time viewing of equipment status, fault diagnosis, and parameter adjustments from off-site locations.

CN

CN English

English