TOFFON Freeze Dryer - Operating Procedures (Part Eight)

Before freeze-drying, the products to be processed should be properly portioned. For fruits and vegetables, pre-treated materials should be placed directly into freeze-drying trays with as large a surface area and as thin a layer as possible. For glass bottles or vials, filling should be even and uniform before loading them into the trays.

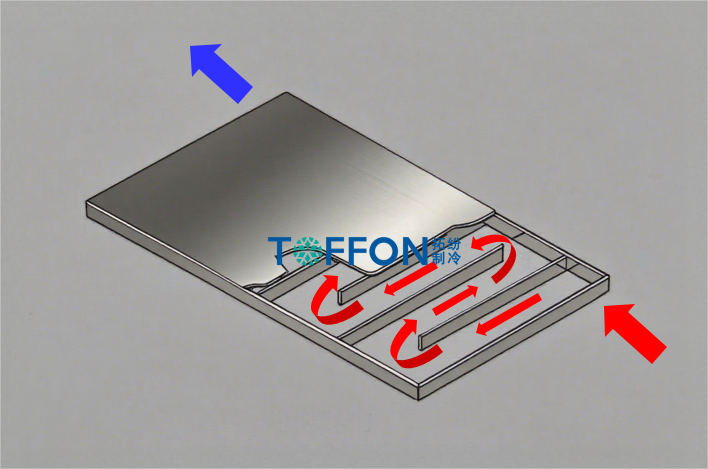

Prior to loading the freeze dryer, the empty chamber must be pre-cooled. The products are then placed inside the chamber for pre-freezing. Before starting the vacuum process, the condenser should be activated in advance based on the cooling rate of the refrigeration unit. During evacuation, the condenser should reach a temperature of approximately <-40°C. Once the vacuum level reaches the pre-set value, heating can be applied to the products in the freeze-drying chamber.

The entire sublimation drying process typically takes about 12 to 24 hours, depending on factors such as the type of product, shape and size, loading quantity, freeze-drying curve, and the performance of the equipment.The freeze-drying curve is a graphical representation of the temperature of both the product and the shelves, the condenser temperature, and the vacuum level plotted against time. Generally, temperature is represented on the vertical axis and time on the horizontal axis.

Different products require different freeze-drying curves. Even for the same product, variations in the freeze-drying curve can lead to differences in product quality. The freeze-drying curve is also influenced by the performance of the freeze dryer itself.

Therefore, different products and different freeze dryers require tailored freeze-drying curves.

CN

CN English

English