The application of solid beverage freeze-drying machines in the beverage industry has multiple advantages, including retaining nutrients, enhancing taste, extending shelf life, and facilitating storage and transportation. With the continuous improvement of consumers' demand for beverage quality and health, the application prospects of freeze-drying technology in the beverage industry will be even broader.

Freeze dried fruit tea production: Freeze drying technology is widely used in the production of fruit tea. A small freeze-drying machine used at home can make personal favorite freeze-dried fruit tea and enjoy the fun of making homemade drinks. At the same time, in the beverage industry with high flavor reduction, the freeze-drying fruit tea process solves the problem of poor product restoration and less prominent flavor in the form of spray dried powder or liquid juice in the past. The form and processing method of freeze-dried fruit tea provide a convenient and cost-effective solution for scenarios such as office, home, and travel.

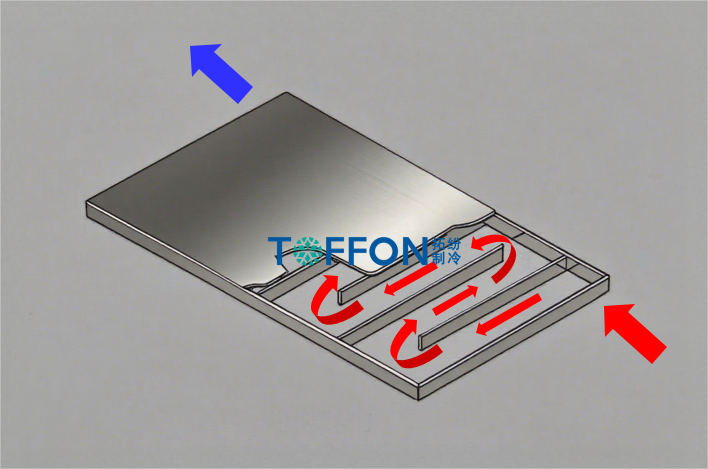

Juice freeze-drying processing: The food freeze-drying machine sublimates the water in the juice into water vapor through three key steps: freezing, vacuum, and sublimation, thereby obtaining juice powder with very little water content. This freeze-dried solid beverage of fruit juice not only retains the freshness and nutrition of the juice, but also extends its shelf life and facilitates storage and transportation. In addition, freeze-drying technology can also be applied to the processing of various fruit juices such as citrus juice, berry juice, nut juice, etc.

Solid beverage production: Freeze dryers play an important role in solid beverage production. It can process various solid beverage products including coffee, tea, chocolate, milkshakes, etc. Through freeze-drying technology, these liquid beverages can be transformed into solid forms that are easy to carry, store, and drink, meeting the different needs of consumers.

Maintaining nutrition and taste: Freeze drying technology can maximize the retention of nutrients and taste in beverages. During the freeze-drying process, by avoiding high temperature heating and oxidation reactions, the nutritional active ingredients such as vitamins and proteins in the beverage are preserved. At the same time, the basic characteristics such as color, aroma, and taste of the beverage can also be maintained unchanged, making freeze-dried beverages closer to the original liquid beverage in terms of nutritional value and taste.

Efficient energy saving and process control: Modern freeze-drying equipment adopts advanced automation control systems and energy-saving designs, which can achieve precise temperature, pressure, and time control, improve production efficiency, and ensure stable product quality. At the same time, the equipment also has the characteristics of high efficiency and energy saving, which can complete the dehydration process under low temperature and low pressure conditions, reduce energy consumption and minimize the impact on the environment.

Small household freeze-drying machines have advantages in solid beverage processing, such as high efficiency and convenience, retention of nutrients, preservation of taste and flavor, extension of shelf life, adaptability to diverse needs, and environmental protection and energy conservation. These advantages make small household freeze-drying machines an ideal choice for families and small workshops to produce high-quality freeze-dried solid beverages.

CN

CN English

English