Flower freeze dryer, also known as fresh flower freeze dryer, is a device used to freeze and vacuum stabilize fresh flowers. It sublimates and removes moisture from flowers in the form of solid ice by controlling temperature, humidity, and vacuum conditions, achieving the freeze-drying process of flowers. This freeze-drying method can preserve the original nutrients, shape, color, and aroma of flowers, while extending their shelf life and preservation time.

The flower freeze dryer (fresh flower freeze dryer) usually includes the following main components:

Refrigeration system: The refrigeration system includes components such as a compressor, expansion valve, condenser, and evaporator, which are used to provide a low-temperature environment and achieve temperature control during the rapid freezing and drying process of flowers, as well as the condensation of water vapor from the sublimation of material samples.

Vacuum system: The vacuum system includes vacuum pumps, valves and pipelines, vacuum gauges, sealing devices, etc. It creates and maintains a vacuum environment in the drying chamber throughout the entire freeze-drying process. Encourage flowers that freeze at low temperatures to directly convert water from the flowers into gas in a vacuum environment, thereby achieving freeze-drying treatment of the flowers.

Control system: The control system includes equipment such as temperature controller, humidity controller, vacuum degree monitor, etc., which are used to monitor and adjust the temperature, humidity, and vacuum degree during the freeze-drying process, ensuring the stability and controllability of the entire freeze-drying process.

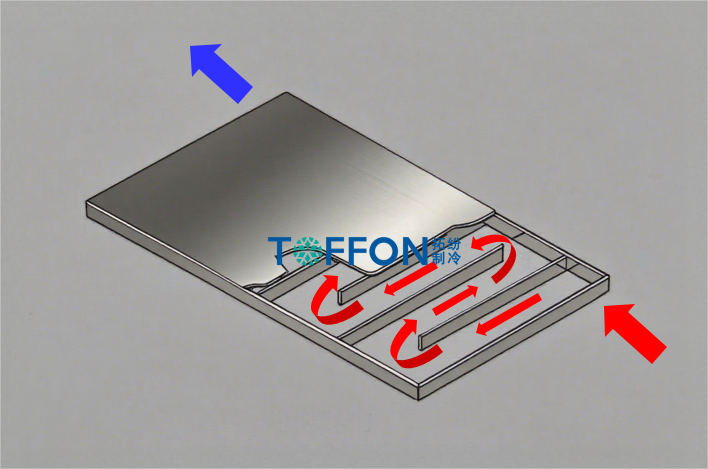

Circulating system: During the freeze-drying process of fresh flowers, the circulating temperature control system provides the temperature required for the flowers to freeze and sublimate, ensuring the freeze-drying quality and drying efficiency of the flowers.

Freeze drying chamber: The drying chamber is the main area for freeze-drying, usually made of stainless steel or other corrosion-resistant materials, with certain anti-corrosion, sealing, and high vacuum resistance properties.

The working principle of the flower freeze-drying machine mainly includes the following steps:

Flower pretreatment: Before entering the freeze-drying machine, flowers need to be pre treated, including trimming, cleaning, and removing unnecessary parts, and ensuring their dry state.

Freezing stage: The flowers are placed in a low-temperature environment in a freeze dryer to quickly freeze them. Low temperature can prevent water in flowers from freezing, and instead exist in the form of ice crystals. This helps to protect the shape and structure of the flowers.

Drying stage: In a low-temperature environment, by controlling the vacuum degree and temperature, the frozen moisture is directly converted into water vapor, thereby thoroughly drying the flowers. This process is called sublimation, which can effectively preserve the color, shape, and aroma of flowers.

Packaging stage: After drying, the freeze-dried flowers have extremely low moisture content. To ensure the quality and storage time of flowers, it is necessary to seal the packaging in a dark place.

The advantages of flower freeze-drying machine include:

Preserving the natural beauty of flowers: The freeze-drying process can reduce water loss, preserve the original nutrients, shape, color, and aroma of flowers, making them look more natural and beautiful.

Extended shelf life: Freeze drying technology can extend the shelf life of flowers, allowing them to remain vibrant and intact for a longer period of time.

Convenient storage and transportation: freeze-dried flowers are not easily spoiled and are not easily affected by external environments, making them easy to store and transport.

Flower freeze-drying machine (flower freeze-drying machine) has a wide range of applications in multiple fields:

Flower preservation: After freeze-drying treatment, flowers can remain bright and intact for a long time, extending their shelf life and allowing them to be displayed in flower shops or homes for a longer period of time, enhancing their ornamental value.

Art Decoration: Freeze dried flowers can be used to make various floral decorations, such as dried flower bouquets, flower garlands, wall hangings, etc. They are used for home decoration, wedding decoration, hotel decoration, and other occasions to beautify the environment and create a romantic atmosphere.

Flower trade: Freeze dried flowers can be transported and stored over long distances, making them suitable for flower export trade and providing more flower sales options for cross-border e-commerce.

Food processing and tea beverage market: Freeze dried flowers can be used to make food products such as flower tea, floral spices, etc., increasing the taste and nutritional value of the products. With people's increasing attention and pursuit of healthy drinks, the demand for floral foods such as flower tea in the market is constantly increasing. For example, making flower tea, floral spices, etc., to increase the quality and taste of the products.

Floral design: In the field of floral design, freeze-dried flowers can be used to create floral works such as dried flower paintings, dried flower ornaments, etc., enriching the material selection and creative methods of floral design.

Gift customization: Freeze dried flowers can be used to make various gifts, such as dried roses, dried flower balls, etc., becoming a unique gift customization choice.

Flower freeze-drying machine is a technology that preserves the nutrients, beauty, and aroma of flowers through freeze-drying, extending their shelf life. The fresh flower freeze dryer has broad development prospects in various fields such as fresh flower preservation, trade export, floral decoration, gift customization, and food processing. With the increasing demand for diversity and high quality of flower products, the market prospects of flower freeze-drying machines are promising and have good development potential.

CN

CN English

English