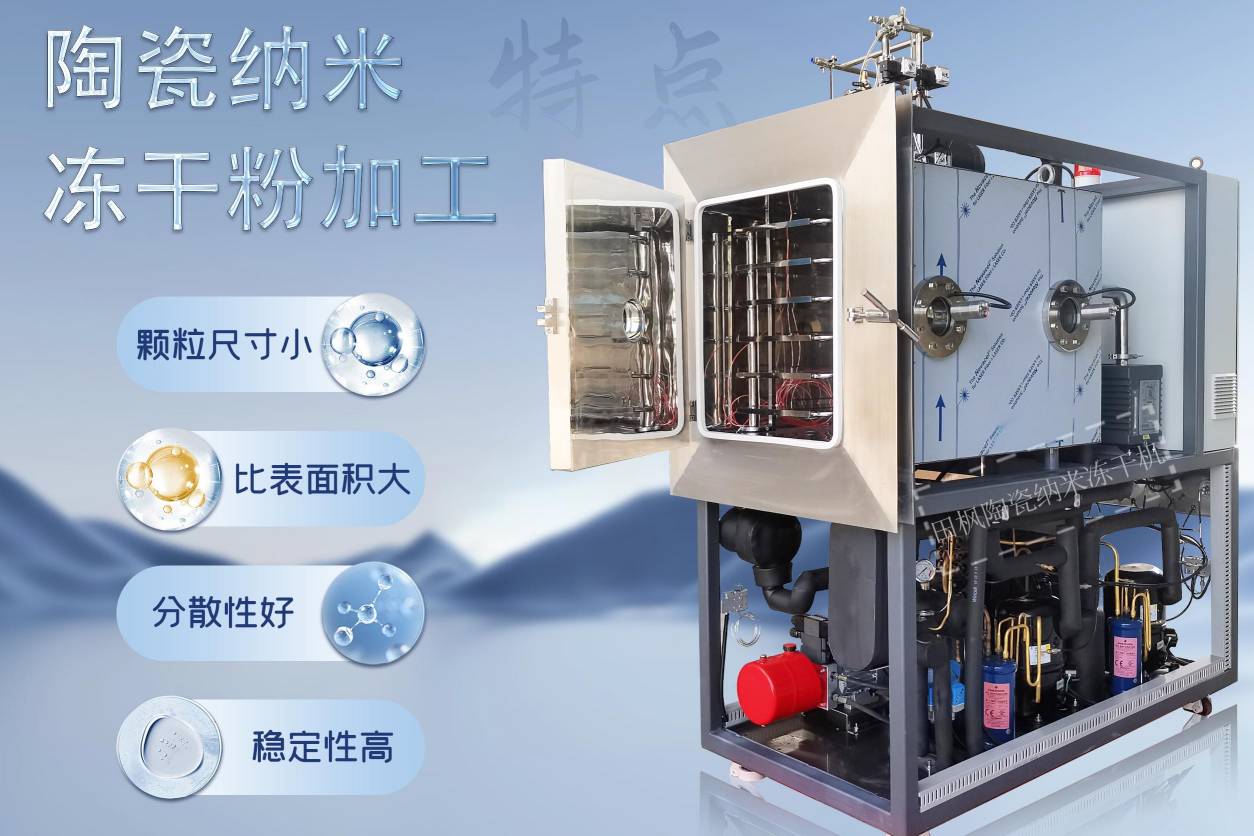

Freeze dryer plays a vital role in the production of nano powder. Freeze drying technology, with its unique treatment method, ensures the purity, quality and activity of nano powder, making it widely used in various fields. This article will discuss how to improve the quality and function of nano powder through fine technology.

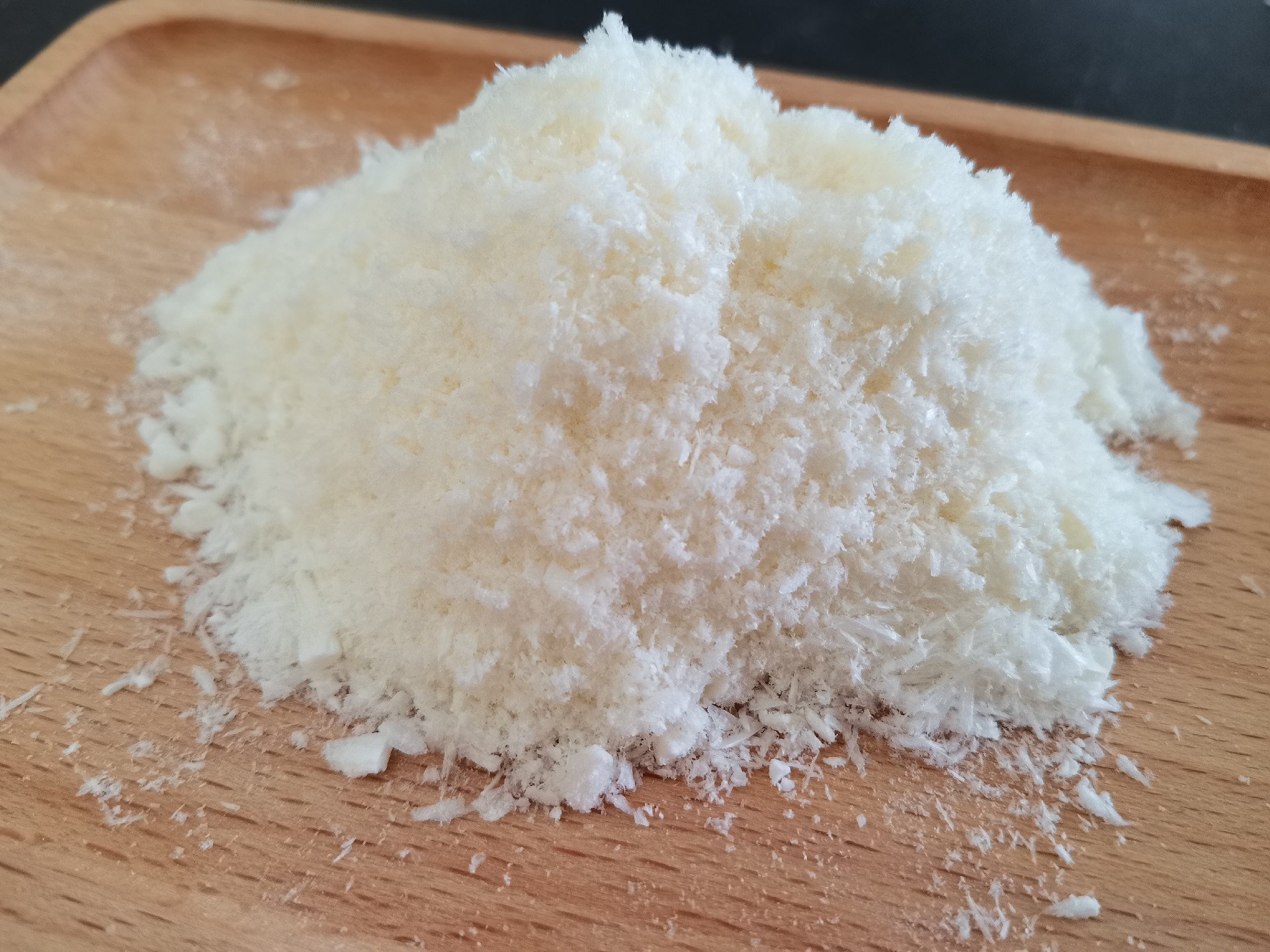

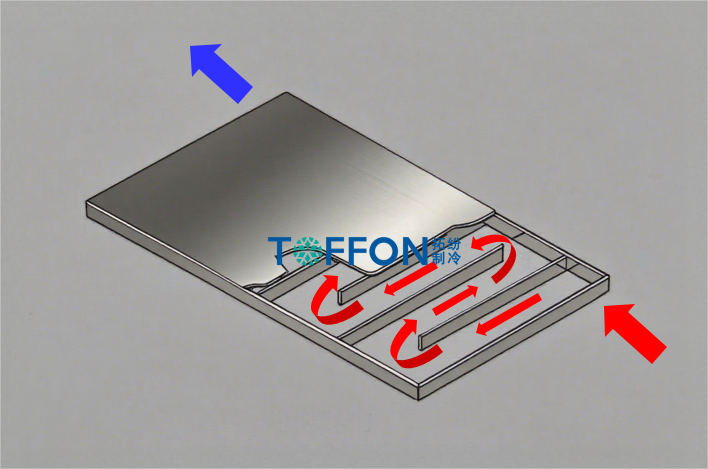

Freeze dryers mainly process samples through freezing and vacuum drying processes. In the initial stage, the sample is rapidly frozen to extremely low temperatures, which can quickly turn the moisture in the sample into ice crystals. These ice crystals are converted into gaseous water vapor during the subsequent drying stage, avoiding the presence of liquid water and reducing the degradation of thermosensitive components in the sample. For nano powder, this treatment method can effectively maintain the original structure and chemical properties of its small particles.

The activity of nano powder is the key to its application effect. Traditional drying methods may damage the surface active components of nano powder, thus affecting its performance. Freeze drying technology, through gentle processing, can maximize the retention of these active ingredients, allowing them to still function as expected in the final product. This makes the freeze-dried nano powder have higher activity and effectiveness in medicine, cosmetics, material science and other fields.

In addition, the operation process of the freeze dryer can effectively avoid the problems of pollution and cross contamination. During the freeze-drying process, the sample is placed in a closed environment and the operation is carried out at low temperature and low pressure, which reduces the interference of external environment on the sample. This ability to control the environment is crucial for the production of high-purity nano powders, because any minor pollution may affect the quality of the final product.

In general, through its precise process, the lyophilizer not only improves the pure quality of nano powder, but also maintains its active ingredients, making its effect in application more stable and reliable. With the progress of technology, freeze-drying technology is expected to bring more innovative solutions for the production of nano powder in the future, and further promote the development of related industries.

CN

CN English

English