Freeze drying technology, also known as freeze-drying, is a method of removing moisture from substances and is widely used in various fields such as pharmaceuticals, food, and biotechnology. As the core equipment for implementing this process, the principle and technological progress of freeze-drying machines continue to drive the development of related industries.

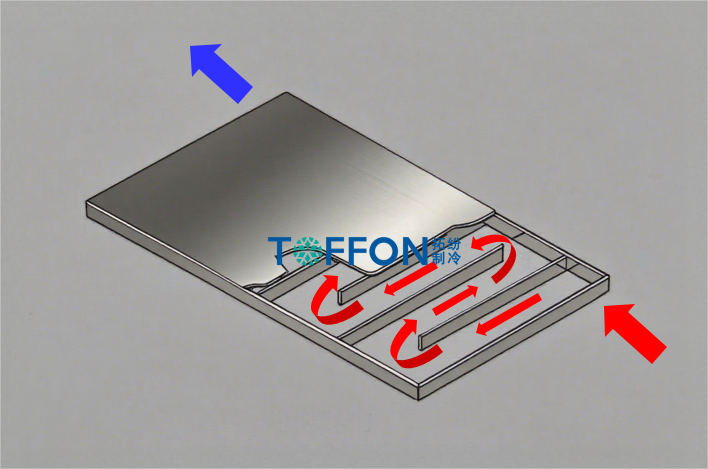

The basic principle of freeze-drying is to freeze the sample to an extremely low temperature, and then in a vacuum environment, the solid water is directly sublimated into gas, thereby removing the water. This process not only effectively maintains the structure and composition of the substance, but also extends its shelf life. Especially in the pharmaceutical industry, freeze-dried formulations can maintain the active ingredients of drugs, ensuring their safety and effectiveness during use.

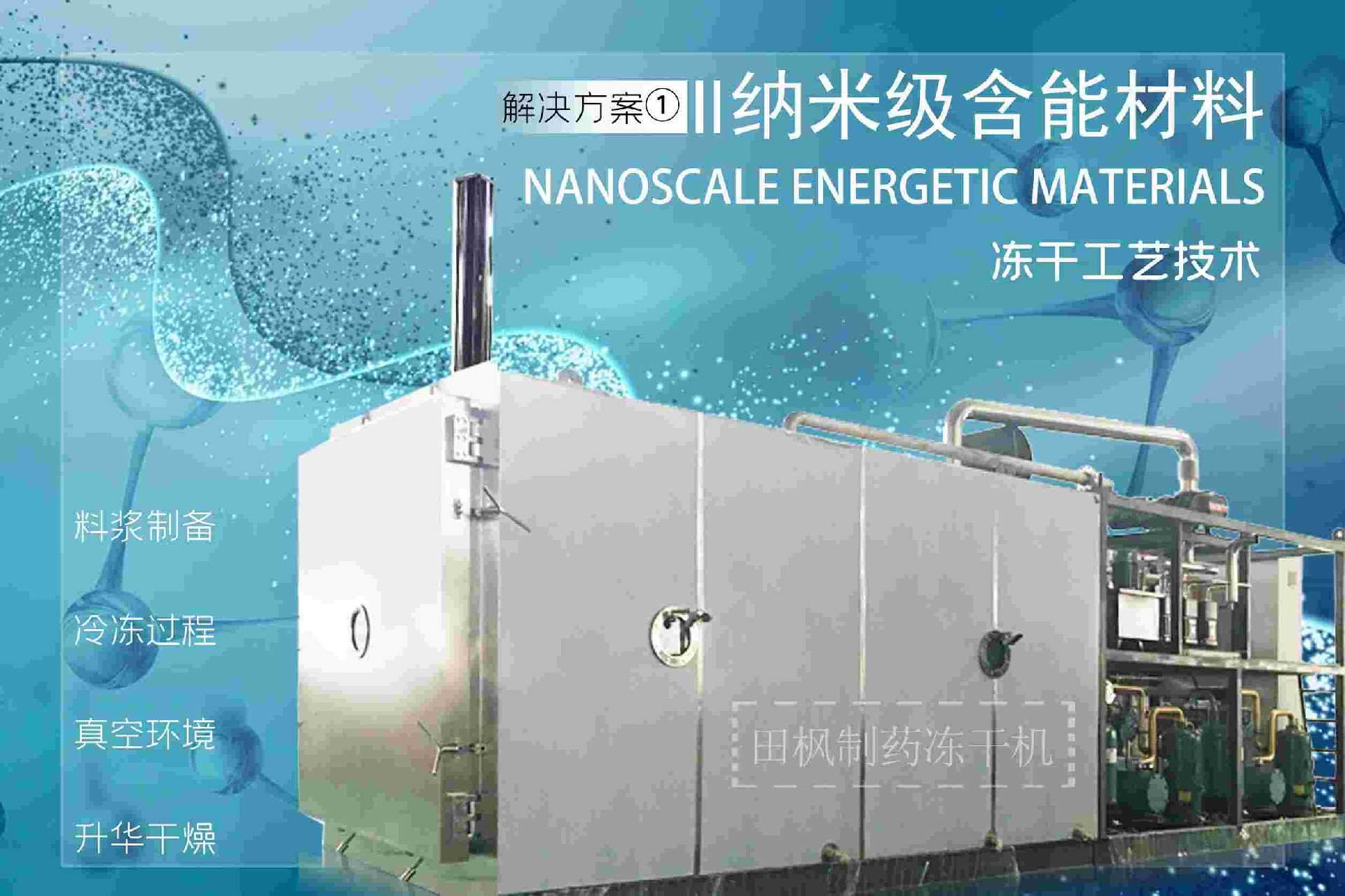

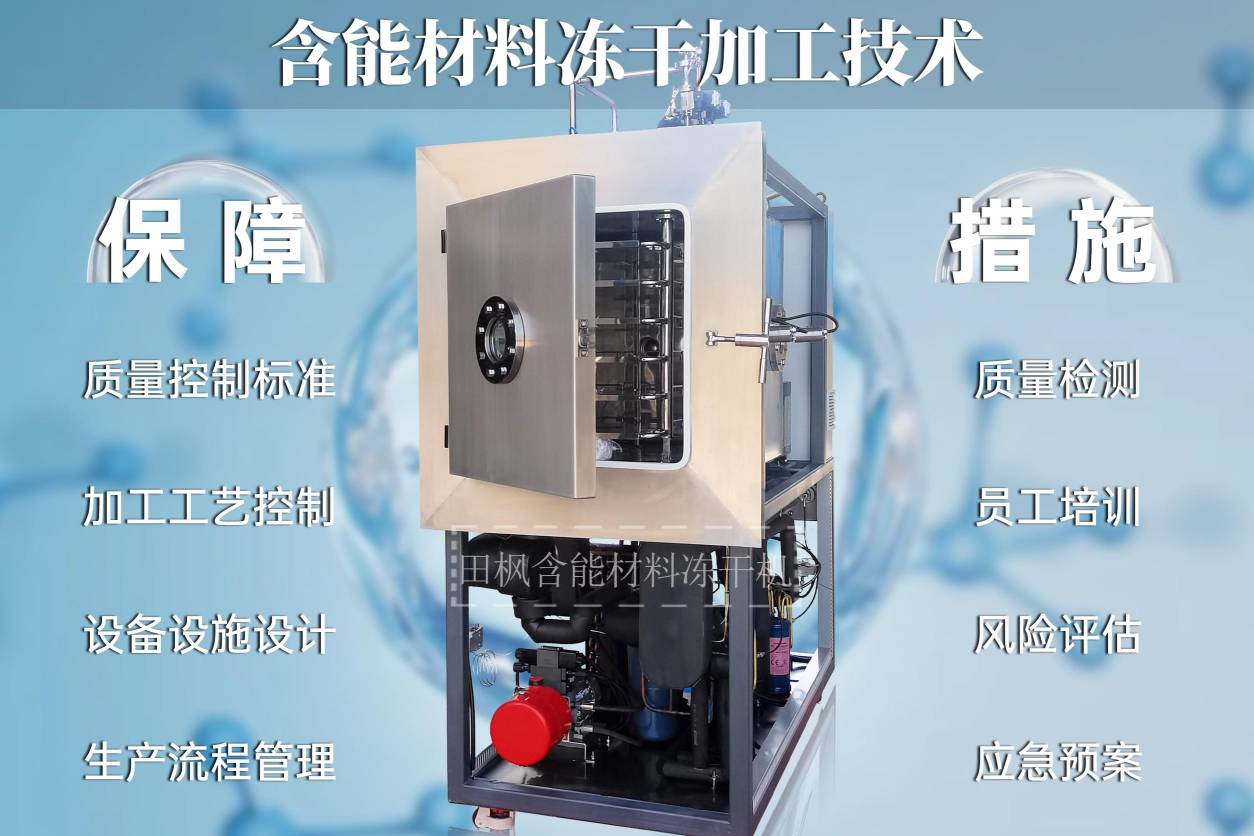

In recent years, technological advancements in freeze-drying machines have significantly improved their performance and efficiency. Modern freeze-drying machines adopt advanced control systems and sensor technology, which can accurately monitor temperature and pressure changes during the freeze-drying process. This real-time monitoring not only improves the freeze-drying effect, but also reduces the potential losses caused by improper operation. In addition, the new freeze-drying equipment has also been optimized in terms of energy consumption, reducing operating costs and improving economic benefits.

In the field of materials science, the application scope of freeze-drying technology is constantly expanding. In addition to traditional drugs and biologics, many foods such as fruits, vegetables, and meat have also begun to use freeze-drying treatment. This method not only maintains the nutritional content and flavor of the ingredients, but also makes the product lightweight and easy to store, making it convenient for consumers to use. With people's increasing attention to healthy eating, the freeze-dried food market is showing a rapid growth trend.

At the same time, the design of freeze-drying machines is becoming increasingly intelligent. Many manufacturers have launched highly automated freeze-drying systems, which can achieve fully automated production, reduce manual intervention, and improve production efficiency. These smart devices also have data recording and analysis functions, helping enterprises better manage production processes and ensure product quality.

In short, as the core equipment of freeze-drying technology, the scientific foundation and technological progress of freeze-drying machines are constantly driving the development of various industries. From pharmaceutical preparations to food processing, freeze-drying technology has demonstrated its extensive potential for application. With the continuous advancement of technology, we have reason to believe that freeze-drying technology will make breakthroughs in more fields in the future, bringing greater convenience and value to human life.

CN

CN English

English