TOFFON Freeze Dryer - Principles of Freeze Drying (Part One)

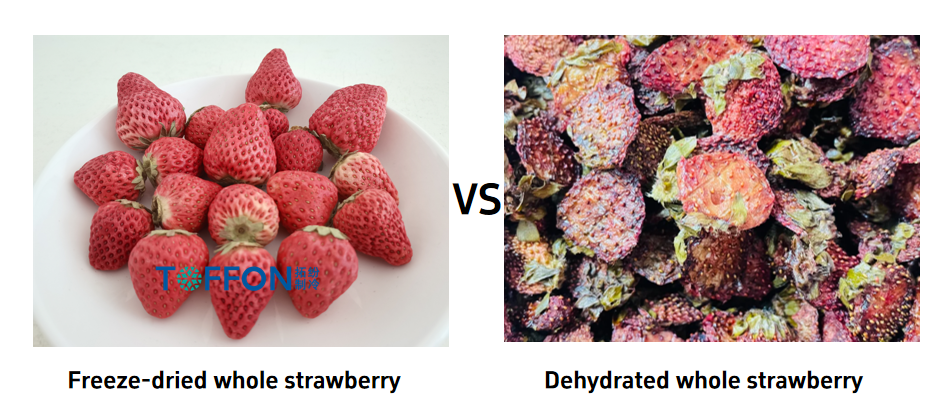

Drying is one of the critical methods to prevent material from spoiling or deteriorating. Traditional drying techniques include sun drying, boiling drying, hot air drying, spray drying, and vacuum drying, among others. These methods generally operate at temperatures above 0℃ or even higher. However, materials dried using these methods often suffer from issues such as volume shrinkage, texture hardening, partial component oxidation, and loss of nutrients.

Heat-sensitive substances, such as proteins and vitamins, may undergo denaturation, and microbial activity can be lost. The solubility of the dried product in water tends to be low, and its physical and chemical properties significantly differ from those before drying.

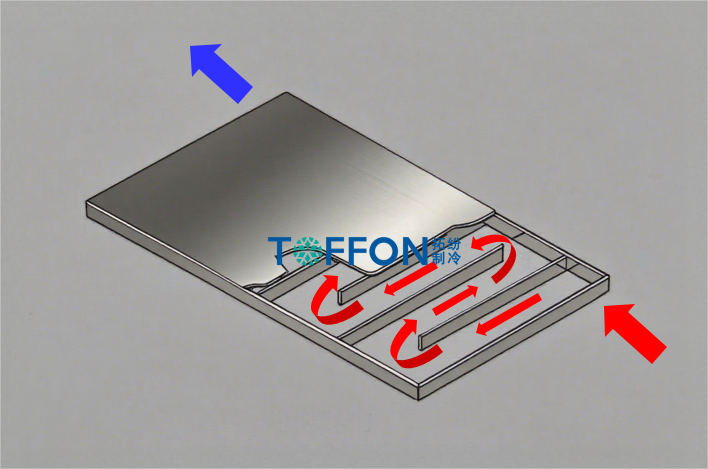

In contrast, freeze dryers exhibit distinct advantages. Freeze drying primarily occurs at temperatures below 0℃, where drying takes place while the material is completely frozen. The process involves first freezing the water-containing material and then sublimating the ice crystals directly into water vapor under vacuum conditions. Since the structure of the material is fixed during the freezing process, it retains its original appearance and state after sublimation. The dried product maintains almost the same volume, featuring a porous and loose texture.

This method ensures that the material's properties are preserved more effectively compared to traditional drying techniques.

CN

CN English

English