TOFFON Freeze Dryer - Advantages of Freeze Drying (Part Two)

Suitability for Heat-Sensitive Materials: Freeze drying occurs at low temperatures, making it particularly suitable for many heat-sensitive substances. Proteins, peptides, vitamins, and other components do not denature or lose their activity during the process.

Minimal Loss of Volatile Components: Since the drying process takes place at low temperatures, there is minimal loss of volatile components within the material.

Inhibition of Microbial Growth and Enzyme Activity: The freeze-drying process occurs in a vacuum environment, preventing microbial growth and enzyme activity, thus preserving the material's integrity.

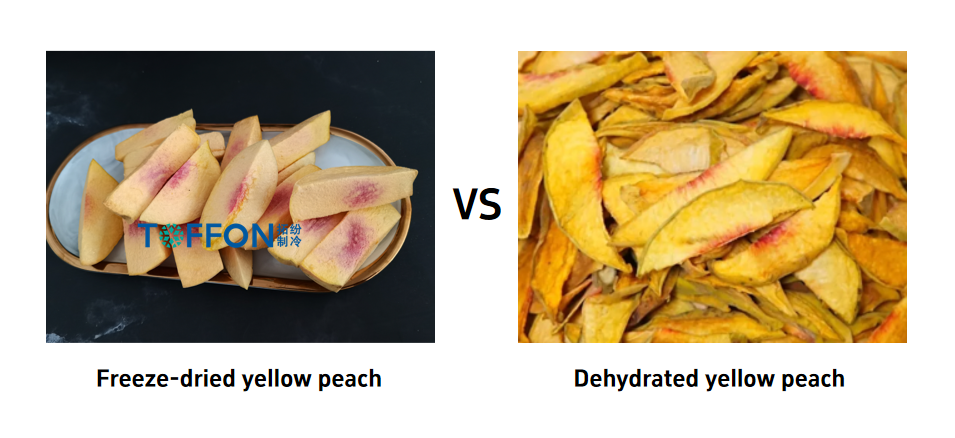

Retention of Original Structure: By first freezing the material, freeze drying ensures that the volume of the material remains almost unchanged after drying, maintaining its original structure.

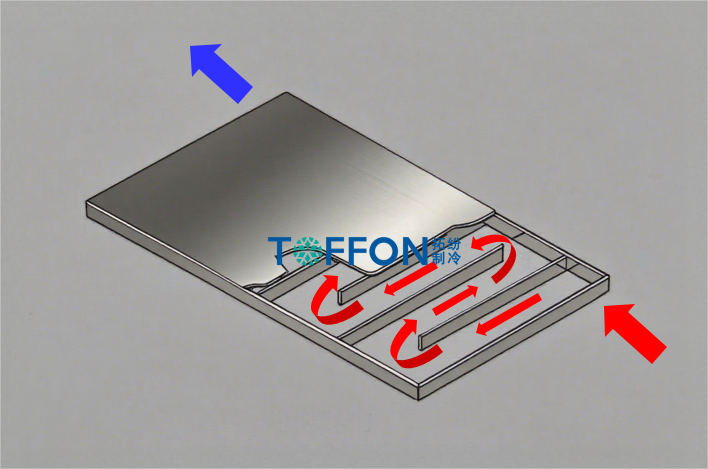

Rapid Rehydration: After freeze drying, the material becomes porous and sponge-like, allowing for rapid rehydration.

Protection from Oxidation: The process takes place under vacuum conditions with low oxygen levels, protecting materials that are prone to oxidation.

High Water Removal Efficiency: Freeze drying can remove over 95% of moisture, enabling the dried products to be stored for 12-36 months. Additionally, the resulting products are lightweight.

Applications: Freeze dryers have been widely applied across various industries, including freeze-dried fruits and vegetables, dairy products, pharmaceuticals, food processing, scientific research, and other sectors. As a manufacturer of freeze dryer equipment, we produce a full range of freeze dryers from experimental and small-scale models to medium-sized, food-grade, and pharmaceutical units. Our products cater to diverse customer needs, with processing capacities ranging from 1kg to 2400kg, and we also support custom non-standard configurations.

CN

CN English

English