TOFFON Freeze Dryer - Components of the Freeze Drying Chamber (Part Three)

Freeze drying of materials requires specialized equipment known as a vacuum freeze dryer, or simply a freeze dryer. This equipment is categorized into several systems: refrigeration, heating, control, vacuum, and the freeze drying chamber. Structurally, it consists of components such as the freeze drying chamber, condenser, vacuum pump, valves, and electrical control elements.

Freeze Drying Chamber

The freeze drying chamber is a high-low temperature box capable of cooling down to below -40°C and heating up to over +50°C. It can also be evacuated to create a vacuum environment. This chamber is the primary component of the freeze dryer. Materials requiring freeze drying are placed on trays within the chamber, which are then positioned on shelves inside the freeze drying chamber. During the freeze-drying process, the material is first frozen, and then heat is applied under vacuum conditions to sublimate the water content within the product.

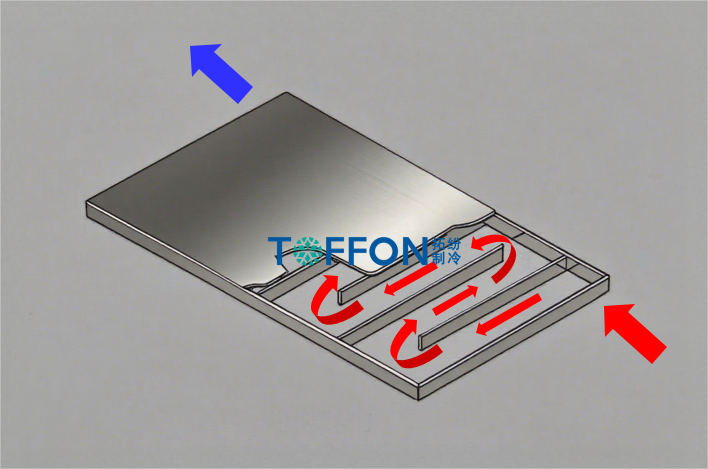

Condenser

To prevent the re-entry of sublimated water vapor back into the material or to avoid damaging components like the vacuum pump, a condenser is installed within the freeze drying chamber. The condenser features a large surface area metal adsorption plate that can cool down to below -40°C and maintain this low temperature. This allows the water vapor sublimated from the material inside the freeze drying chamber to be captured and frozen onto the metal surface of the condenser, preventing moisture from returning to the material.

Key Features and Functions:

Temperature Range: Capable of reaching temperatures below -40°C for freezing and above +50°C for heating.

Vacuum Capability: Can be evacuated to create a vacuum environment essential for the sublimation process.

Material Handling: Materials are loaded onto trays and placed on shelves within the chamber for processing.

Condenser Functionality: Equipped with a cold trap that efficiently captures and freezes sublimated water vapor, ensuring no moisture returns to the dried material.

This design ensures efficient and effective freeze drying, preserving the quality and integrity of the materials being processed. The precise control of temperature and vacuum conditions, along with the protection provided by the condenser, makes the freeze drying chamber an indispensable part of any freeze dryer system.

CN

CN English

English