TOFFON Freeze Dryer - Refrigeration System of Freeze Dryers (Part 4)

Material freeze-drying must be carried out in specialized equipment, known as vacuum freeze dryers, or simply freeze dryers. Freeze dryers can be categorized by system into refrigeration systems, heating systems, control systems, vacuum systems, and freeze-drying chambers. Structurally, they consist of the freeze-drying chamber, condenser, vacuum pump, valves, electrical control components, and more.

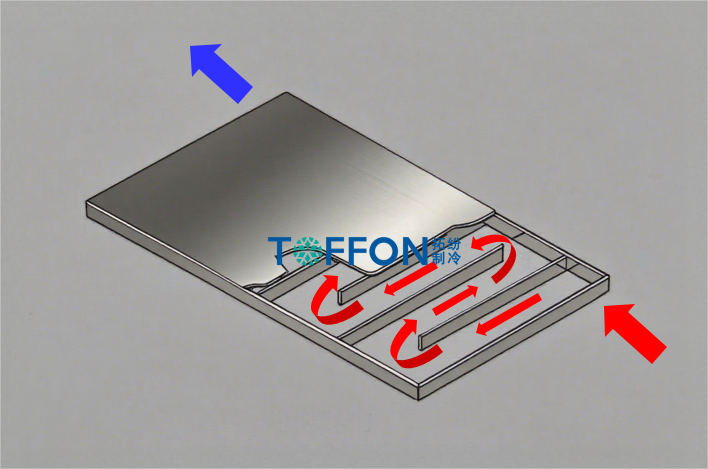

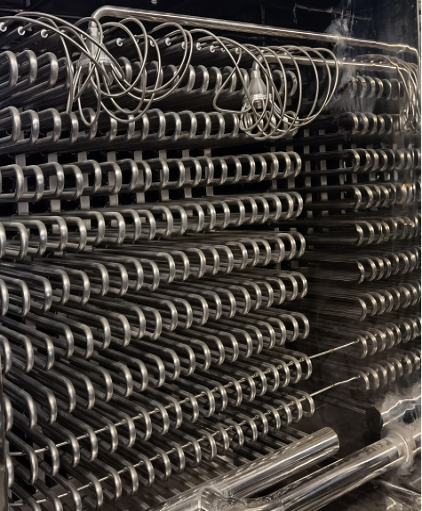

The refrigeration system comprises the refrigeration unit, freeze-drying chamber, condenser, pipelines, and other components. The refrigeration units can be two independent systems or a shared one. The function of the refrigeration unit is to cool the freeze-drying chamber and condenser, generating and maintaining the low temperatures required for their operation. There are two cooling methods: direct cooling and indirect cooling.

The FZG series of food freeze dryers offer batch processing capacities ranging from 50 kg to 2400 kg, meeting the needs of large-scale industrial production across different batch sizes. The entire machine is designed in compliance with food safety production standards and can be used for freeze-drying fruits, vegetables, pet food, coffee, wild mushrooms, and more. The FZG series comes with pre-set freeze-drying processes, saving time on process development, and features simple operation and maintenance.

CN

CN English

English